Having faced multiple challenges onsite with old systems, we thought about adding all the little (and big) extras that will make a difference to you.

- It stacks and packs

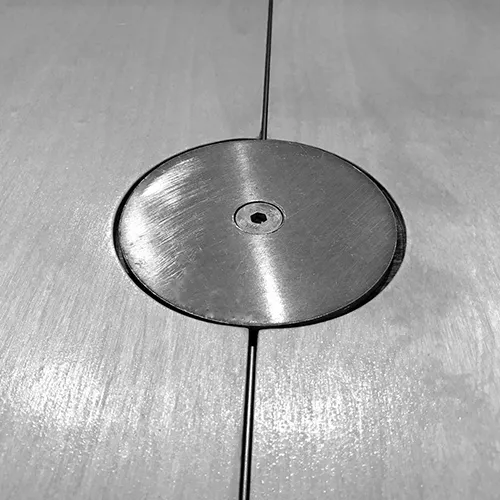

- Self-squaring

- No creep, delivering exceptional accuracy — the advantage of a true grid-based modular staging system

- One tool wonder - just need a podger or mallet

- Ramps and stairs engineered for real-world use, not afterthoughts

- Easy replacement of damaged components — remove, replace and continue

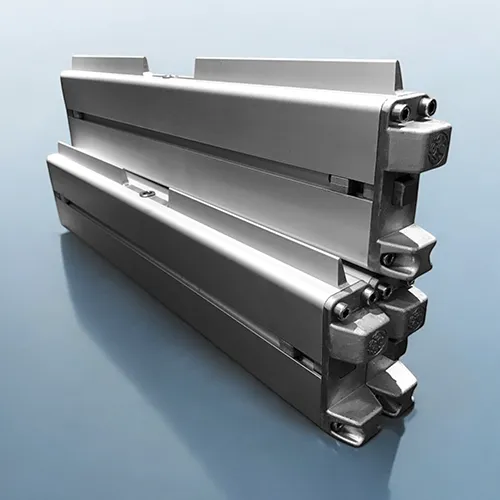

- Two beams make one – four times stronger

- T Slots. If you’re going to design a beam why not have them. We put 5 in just to be safe AND they all line up with each other

- Grid Size – why make a small one when you can make it so much bigger? 8 x 8 Grid 7.5 kN and 1 leg

- Beams and decks that fit between legs – genius

- Flexibility in design – Need a spiral staircase in the middle of the stage? Not a problem

- 48.3 and 60 are the Magic Numbers we all live by. The scaff tube and oversize clamp

- Quiet no creaking

- 2 beam, 1 Crew or 1 Beam, 2 Crew like other systems. We went for efficiency and the first option. Four times more efficient

- On-site manufacturing capability — components can be modified using standard tools such as a saw and router